Products

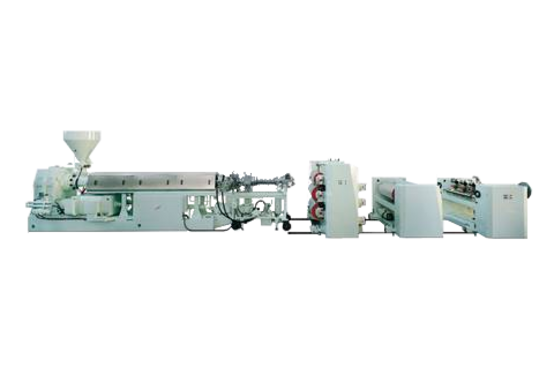

Extrusion Lines

Moulds

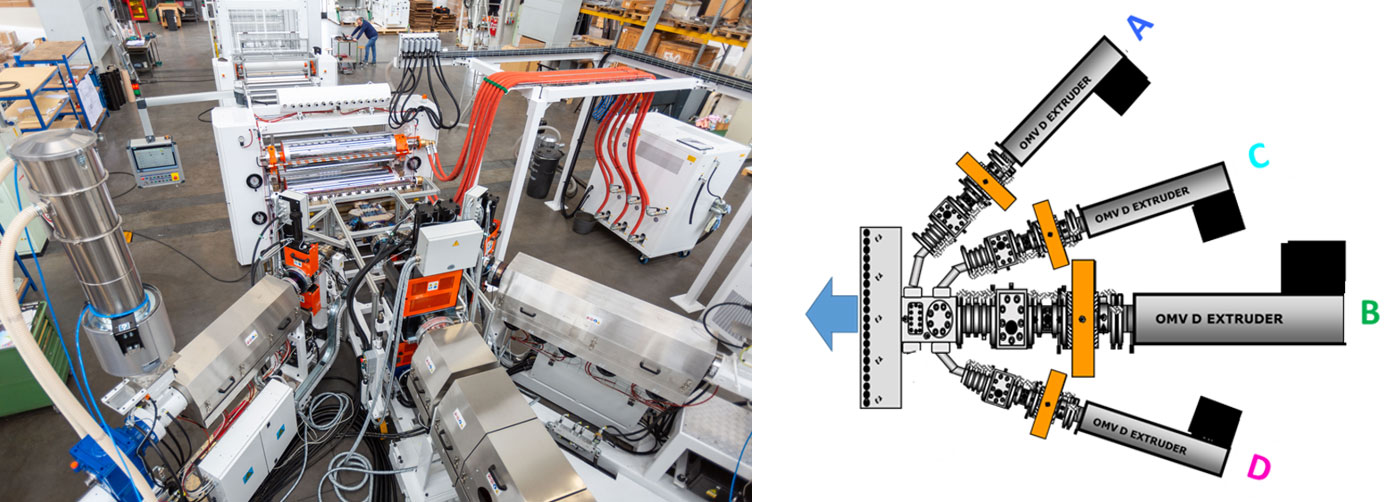

OMV Extruders

OMV Extruders are supplied in a range Ø 45mm (1.77”) to 170 mm (6.7”) and available in four basic models, identified by the chill roll diameters: 750mm(29.5”) / 500mm (19.7”) / 350mm (13.8”) / 250 mm (9.84”). OMV’s screw design caters for the most efficient extrusion of the various polymers (PP-PS-PET-ABS-Multilayer) and custom engineered for special blends or additives. This ensures optimum quality and throughput.

The combination of both in-house testing and feedback of “in-service” machines has allowed OMV to continue to develop extruders that both maximize machine efficiency and suit customers custom requirements.

Today’s extrusion offerings is the result of forty plus years of technology and know-how; constant research coupled with rigorous testing programs has made OMV a world leader in the manufacture of precision extruders for production of high-quality plastic sheet from mono layer to seven-layer barrier structures.

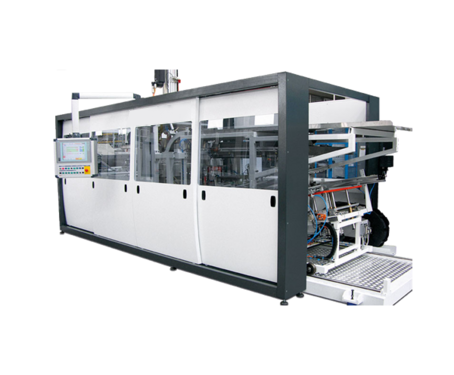

RM77 REVOLVER

OMV international patent “revolving mould” forming technology for highest production and best precision

Forming area: 770 x 480 mm

RM77 “REVOLVER” features a unique, patented “Rotating Mould System” for thermoforming, which allows much longer cooling process at very high speed, especially studied for materials like polyolefins that need longer cooling period. Its forming station and automatic product handling are designed for multiple row moulds, in-line and/or staggered layout.

RM77 is the first machine to break the barrier of 50 cycles per minute with PP cups, a major step forward in thermoforming technology. At its debut in 2016 the machine reached a world-record 174,000 cups per hour, producing Ø71 mm PP drinking cups

Downloads: RM77

F88

The large platen universal thermoformer for shallow products

Forming area: 1280 x 750 mm

F88 is an automatic large-size thermoformer whose special feature is its modular configuration. Available in two different versions:

Single-Station/In-Mould-Trimming (punch-and-die moulds), to produce plates, trays and lids in PS, PP, PLA and other biodegradable materials

Multi-Station/Separate Trimming (steel-rule cutting moulds or punch-and die moulds), to produce trays, baskets, plates, boxes etc. in PET, PS, PLA and other biodegradable materials

Video: OF88 – Plate and tray thermoformer

Downloads: F88

F88 – Precision in every situation

F87

The ultimate large universal thermoformer

Forming area: 850 x 650 mm

F87 is a fully automatic, electro mechanical driven, thermoforming machine with in-mouId trim, which nullifies shrinkage effects on trim accuracy. It has been designed to process all types of thermopIastic materials.

F87’s forming station and automatic product handling is designed for multiple row moulds, in-line and/or staggered layout. The international patented “vacuum plate” and unloading system, including stacking and counting, provides a labor free handling with high hygienic. The design incorporates the “Smart Drive” and the moving parts in automated product handling are made of Iight weight, durable carbon fibre material, which assures optimized cycle speed with lower production costs.

This machine features a special Rim-Rolling System by compression, an OMV Technologies patent, that doesn’t require further product heating.

Video: F87 – Large-platen Cup Thermoformer

Downloads: F87

F87 – Think big

F86

F86 is a fully automatic electro mechanically driven thermoformer with in-mould trim, which nullifies shrinkage effects on trim accuracy, it has been designed to process all types of thermoformable materials, including polypropylene, and coextruded barrier materials.

This machine is characterized by a special ejection and unloading system including a guided vacuum plate, 4-station rotary transport wheel, a stacker, a rotary arm and one unloading robot. In addition, the unloading and transfer conveyors have been especially designed for handling shallow products with minimum stacking height and for eliminating “de-nesting” of different product types thanks to the adjustable inclination setting. There is also available space to install optional quality control station, hole-punch station or other in-line operation before stacking and unloading.

OMV Technologies “quick mould change feature” minimizes down time for mould changes. The cutting device is made by eccentrics placed on the upper press (an OMV Technologies patent).

Video: F86 – Large-platen lid former

Downloads: F86

F86 – Two dynamic versions

E76

OMV Technologies „shuttle mould“ forming technology for higher production requirements

Forming area: 760 x 540 mm

E76 is a fully automatic, electromechanically driven, thermoforming machine with in-mould trim, which nullifies shrinkage effects on trim accuracy. Designed to process all types of thermoplastic and coextruded materials, E76 features the international OMV patent “Shuttle Mould System” which allows cooling 3.5x longer than any conventional machine, particularly suited to materials like polyolefins.

Thanks to the reduced opening stroke of the forming press, this system allows a thermoforming polypropylene cycle speed as high as the polystyrene’s one. E76 also features a special Rim-Rolling System by compression, an OMV international patent, that doesn’t require further product heating. In addition, it also lets unloading and stacking products of different heights.

Video: E76 – Shuttle Mold Technology

Downloads: E76

E76 – The wild one

F37

The medium large universal thermoformer

Forming area: 780 x 420 mm

F37 is a fully automatic, electro mechanically driven, thermoforming machine with in-mould trim, which nullifies shrinkage effects on trim accuracy. Designed to process all types of thermoplastic materials, F37’s forming station and automatic product handling is suitable to multiple row moulds, in-line and/or staggered layout. The international patented “vacuum plate” and unloading system, including stacking and counting, provides automatic and highly hygienic product handling.

F37 features the Smart Drive; moving parts in the automated product handling are made of lightweight, durable carbon composite material, ensuring optimized cycle speed with lower production costs.

This machine incorporates a special Rim-Rolling System by compression, an OMV Technplogies, that doesn’t require further product heating.

Video: E76 – F37 – Universal thermoformer

Downloads: F37

F37 – The smart driver

F33

The swift thermoformer for great many uses

Forming area: 850 x 250 mm

F33 is a fully electrical, in-mould trimming thermoforming machine, designed for multi-row tools.

Flexibility is the keyword for this machine, conceived to process all types of thermoplastic and coextruded materials, independently of type and shape of products. Typical features are its outstanding forming speed and its easy operation. Unique on-board RIM-rolling device available on request.

Video: E76 – F33 – The swift thermoformer

Downloads: F33

F33 – The speedy one

F25

F25 IML – The IML thermoformer for containers, cups and lids

Forming area: 850 x 250 mm

F25/5 IML-T is a fully electrical, automatic thermoforming machine with forming and cutting operation in one station, able to run IML-T containers and lids. Mould closing and cutting operations are performed through a servo-actuated mechanical toggle system.

F25 – The universal Thermoformer

Forming area: 850 x 250 mm

F25/5 is the latest version of a machine sold all over the world in a large number of units since the 70’s: it is a fully automatic, electromechanically driven thermoformer with in-mould trim, which nullifies shrinkage effects on trim accuracy.

Flexibility is the key world for this machine, conceived to process all types of thermoplastic and coextruded material, independently of type and shape of products.

Unique features of the F25/5 is the easy operation and the low level of maintenance required. Its long heating oven allows for production of PP off-line as well as in line, with no preheating and without lowering the cycle speed.

Downloads: F25/5 IML

F25 – The face former

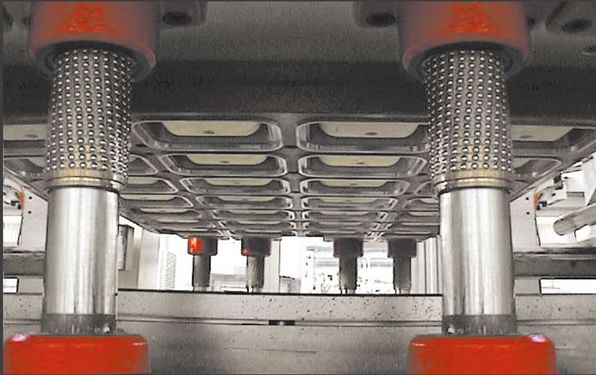

OMV Moulds

Every mould is entirely designed and manufactured by OMV, from product evaluation to tool design, up to the final test, using high quality materials and the most refined techniques. Every mould is designed to achieve maximum production with highest reliability.

Mould parts are manufactured using a range of state-of-the-art digital controlled machines which allow the production of standard components and perfectly changeable spare parts. All mould parts are checked, whether spares or components of a mould to be later assembled.