Manufacturers of Turnkey Extrusion, Thermoforming and Tooling Systems

With over 60 years of expertise manufacturing extruders, thermoformers, and tooling, OMV Technologies stands as a trusted leader in delivering quality, innovation, and durability to the thermoforming industry. Our advanced OMV Thermoforming Machine Equipment is designed to meet the highest standards, offering precision engineering and reliable performance. We specialize in the development of closed-loop turnkey systems, ensuring optimal material utilization, reduced waste, and enhanced efficiency for our clients. Whether you need state-of-the-art extruders, high-performance thermoformers, or customized tooling solutions, OMV Technologies provides cutting-edge technology tailored to your specific manufacturing requirements. Trust OMV for exceptional results in every project.

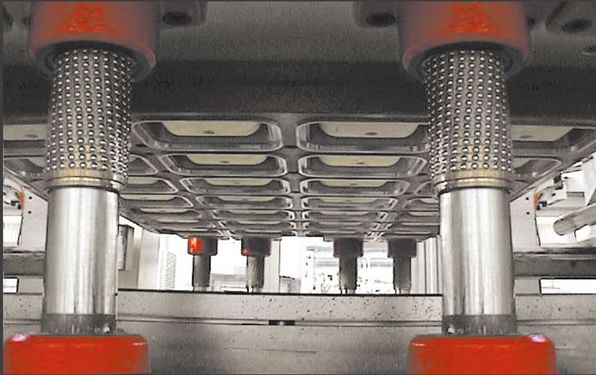

OMV Thermoforming Machine Products & Equipment

Explore OMV’s industry-leading thermoforming solutions, designed for precision, efficiency, and reliability. As experts in manufacturing extruders, thermoformers, and turnkey systems, we deliver cutting-edge technology to enhance your production process and meet the demands of advanced packaging. From high-performance extruders to fully integrated turnkey systems, OMV provides the innovation needed to optimize your manufacturing operations.

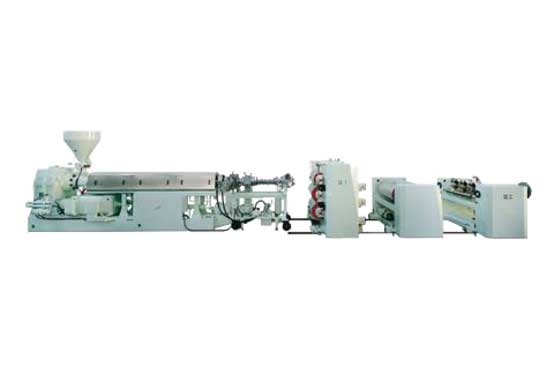

Extrusion Lines

OMV extruders are available in a range of Ø 45 to 170 mm and come in four core models, classified by roll diameter: 750, 500, 350, and 250 mm. Our proprietary, extensively tested screw design—engineered for various materials including PP, PS, PET, ABS, and multilayer structures—is continuously refined to adapt to raw material advancements, ensuring superior quality and maximum throughput.

Download Detailed Information About OMV Thermoforming Machine Equipment

To access detailed technical information about OMV Thermoforming Machine Equipment, please click on the button below for more insights.

Pioneering Innovation in Thermoforming & Extrusion

With 60 years of expertise, OMV Machinery, Italy has been a trailblazer in the extrusion and thermoforming industry, introducing many of the advanced features that set industry standards today. Renowned for our closed-loop turnkey in-line extrusion, thermoforming, and tooling systems, we continue to push the boundaries of technology to maximize manufacturing efficiency. From advanced extrusion systems and precision oven heating controls to superior forming techniques and sustainable energy and material conservation initiatives, OMV remains the go-to solution for cutting-edge thermoformed packaging solutions.”