Manufacturers of Turnkey Extrusion, Thermoforming and Tooling Systems

Products

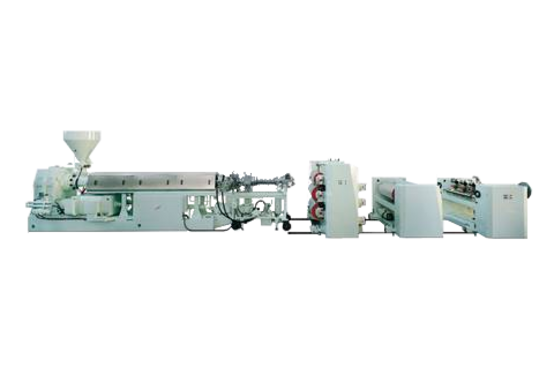

Extrusion Lines

OMV Extruders are supplied in a range Ø 45 ÷ 170 mm. They come in four basic models, identified by the rolls diameter: 750, 500, 350, 250 mm. The original, thoroughly tested OMV extruders’screw design for various materials (PP-PS-PET-ABS-Multilayer) is constantly upgraded to fit raw materials’ improvements, so as to achieve optimum quality and throughput.

Downloads

To access our technical information, please click on the button below.

Drinking Cups, Deli Cups, Portion Containers and Lids

First to Market with Unique Advanced Manufacturing Features

OMV Machinery, Italy has 60 years of experience in the extrusion and thermoforming industry and were first to market with many of the advanced features utilized today. OMV are renowned for their closed loop turnkey inline extrusion, thermoforming and tooling systems and continue to offer cutting edge technology to ensure maximum manufacturing efficiencies. The advanced technologies included in the extrusion systems to the oven heating controls to superior forming techniques along with energy and material conservation initiatives makes OMV the go to solution for all thermoformed packaging needs.

Technologies

Click on categories below to see more

Technology Center

OMV Italy boasts a comprehensive Technology center where resin blends, extruded sheet and inline thermoformed parts are prototyped.

Trim in Place

Specialize in the match metal Punch and Die in-mold trim tooling technology.

Air Savings device

OMV’s unique Air Savings Technology ensures minimal compressed air usage.

Product flange coining

Superior control of tooling coining feature from operator control screens.

Online Rim Rolling

OMV’s patented online rim rolling ensures high quality rim rolled round and non-round containers from cycle to cycle and run to run.

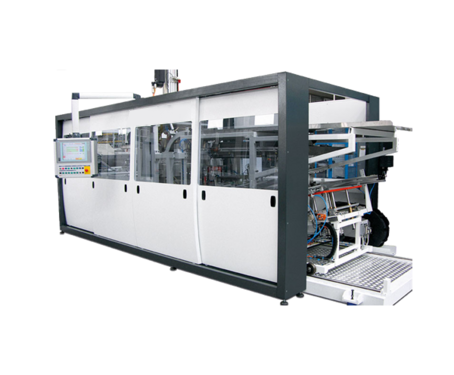

Closed Loop, Turnkey systems

One Stop Shop for all your extrusion and thermoforming needs. From resin blending, conditioning, extrusion inline with thermoforming and web handling.

100% PCR Utilization

To meet new single use plastic legislation, OMV ensure the most efficient introduction of PCR Flake while maintaining quality and run efficiencies.

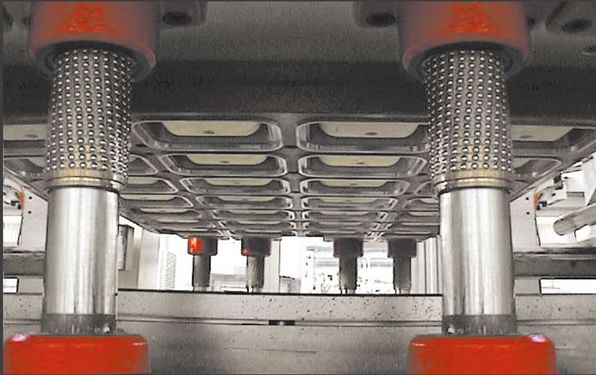

Advanced mold cooling

OMV’s mold cooling stations, ensure the maximum efficiencies for high-speed forming, to ensure minimal post molding shrinkage.

Extrusion Auto Purge

Pre-programmed purge feature to ensure maximization of purging procedure and minimal material wastage and downtime

Customized Systems

Modular design of machinery components allow for customization of machinery around the product. This ensures optimal manufacturing efficiencies.